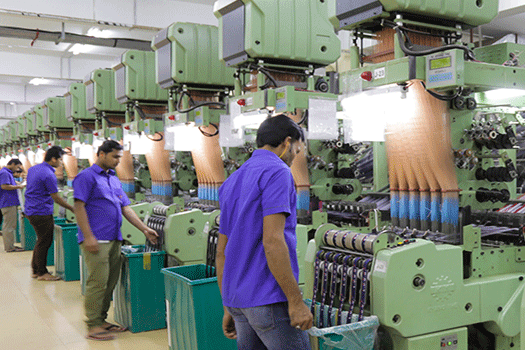

ExpoTrims Industries is one of the largest & leading garments accessories manufacturer in Bangladesh since 2017. The facilities are well equipped with state of the latest machineries and backup the dynamic team. As time passed be and we have centralized our all production. Our focus one of the development of customized new product and productivity, facilities, quality & delivery.

In a changing world, the importance of quality systems (QSs) in organizations’ excellence has been felt more and more, because it ensures consistent and desired product quality. EXPO TRIMS INDUSTRIES believes the scope for quality improvement is always there and success comes through proper monitoring and effective action plan.

Garment accessories encompass a diverse range of supplementary items that complement clothing, such as buttons, zippers, ribbons, and patches. They contribute both aesthetically and functionally to clothing, enhancing design and aiding in practicality. These accessories play a crucial role in achieving desired styles and ensuring clothing’s overall appeal and utility.

Poly Bag:

Twill Tape:

Plastic Clip:

Screen Print:

Woven Label:

Swarovski Crystals: Swarovski crystals are high-quality precision-cut crystals known for their exceptional sparkle and brilliance. They are often used to embellish garments, accessories, and even footwear.

Metallic Chains and Hardware: Metallic chains, studs, grommets, and other hardware are frequently used to add a bold and edgy aesthetic to garments and accessories like handbags, belts, and footwear.

Leather and Faux Leather: Leather and faux leather are classic materials used for various garment accessories such as belts, gloves, and patches. They add a touch of luxury and durability to items.

Velvet and Satin Ribbons: Velvet and satin ribbons are used for decorative purposes, such as creating bows, trims, and closures on garments and accessories.

Embroidered Patches: Embroidered patches are fabric pieces embellished with intricate designs using threads. They are commonly used to add a personalized and artistic touch to denim jackets, bags, and hats.

Sequins and Beads: Sequins and beads are often sewn or glued onto garments and accessories to create eye-catching patterns, textures, and embellishments.

Fur and Faux Fur: Fur and faux fur are used for trims on items like coats, hats, and accessories, providing both warmth and a luxurious appearance.

Lace and Crochet: Lace and crochet materials are delicate and intricate, often used for decorative edging, overlays, and panels on garments like dresses and blouses.

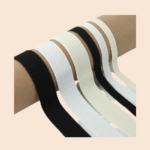

Elastic Bands: Elastic bands can be both functional and decorative. They are used in waistbands, cuffs, and other areas where stretch and comfort are required.

Buckles and Fasteners: Buckles and fasteners come in various designs and materials like metal, plastic, and even wood. They are essential for belts, bags, and other closures.

Pearls: Pearls, whether natural or imitation, add elegance and sophistication to accessories like necklaces, earrings, and hairpins.

Acrylic and Lucite: These materials are often used to create bold and statement-making jewelry and accessories due to their transparency and vibrant colors.

Supplier Selection and Approval: The first step is to identify and select reliable suppliers for the garment accessories. Suppliers should have a track record of producing high-quality products and adhering to industry standards.

Specification Development: Clear and detailed specifications should be developed for each type of accessory. These specifications should outline the required materials, dimensions, colors, finishes, and any other relevant characteristics.

Incoming Material Inspection: When the accessories arrive at the manufacturing facility, they should undergo an initial inspection to ensure they match the provided specifications. This might involve measuring dimensions, checking color consistency, and verifying the quality of materials.

In-Process Inspections: During the manufacturing process, various checkpoints should be established to inspect the accessories at different stages. This helps identify and rectify any issues early in the production process.

Functional Testing: Depending on the type of accessory, functional tests might be necessary. For example, zippers might be tested for smoothness of operation, buttons for secure attachment, and labels for legibility and durability.

Visual Inspection: A visual inspection is essential to identify any defects in appearance, such as scratches, discolorations, misalignments, or inconsistencies in printing or embossing.

Sampling: Random samples of accessories should be selected from production batches and thoroughly inspected to ensure representative quality.

Lab Testing: Some accessories might need to undergo laboratory testing, especially if they have specific performance requirements, such as buttons needing to withstand a certain amount of force.

Packaging Inspection: The quality of packaging materials, labeling, and correct quantities of accessories per package should be verified.

Documentation and Records: All inspection results, testing outcomes, and related data should be documented for traceability and analysis. This documentation is essential for addressing any quality issues and for future reference.

Final Inspection: Once the accessories are ready for shipment, a final inspection should be conducted to ensure that the overall quality meets the set standards.

Feedback and Continuous Improvement: If any defects or issues are identified, feedback should be provided to suppliers, and corrective actions should be taken to prevent similar issues in the future. This continuous improvement process helps enhance the overall quality of the accessories.

Compliance with Regulations: Depending on the region and industry, there might be specific regulations or standards that the garment accessories need to comply with, such as safety regulations regarding the use of certain materials.

Our employees are our most significant and essential resources. We believe it to be our most basic duty to treat every employee fairly, equally, impartially, and respectfully. Using tools such as audits and inspections, we strive to ensure our employees’ rights are upheld without exception. And established mechanisms are used to enable and encourage all employees in every one of our locations to address and communicate with management regarding any issue.

Production per month

Looms in Total in All Shades

Powerful Generator Available

© 2023 EXPO TRIMS. All rights reserverd.

House No. 482, (1st Floor), Road No. 03, Sector No. 12, Uttara, Dhaka-1230, Bangladesh.

52/1, West Rajashan, Savar,

Dhaka-1340, Bangladesh.

Contact Now