Supplier Selection and Approval: The first step is to identify and select reliable suppliers for the garment accessories. Suppliers should have a track record of producing high-quality products and adhering to industry standards.

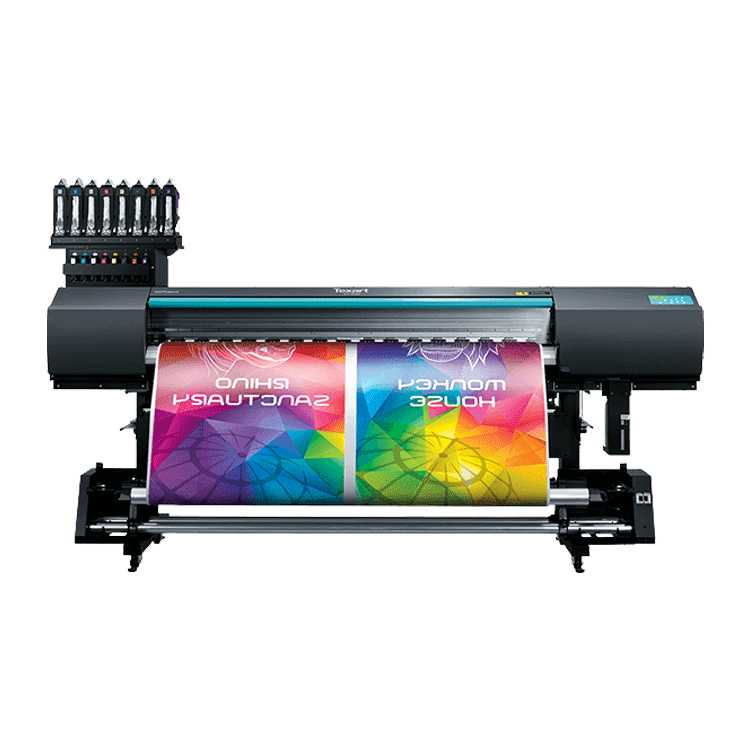

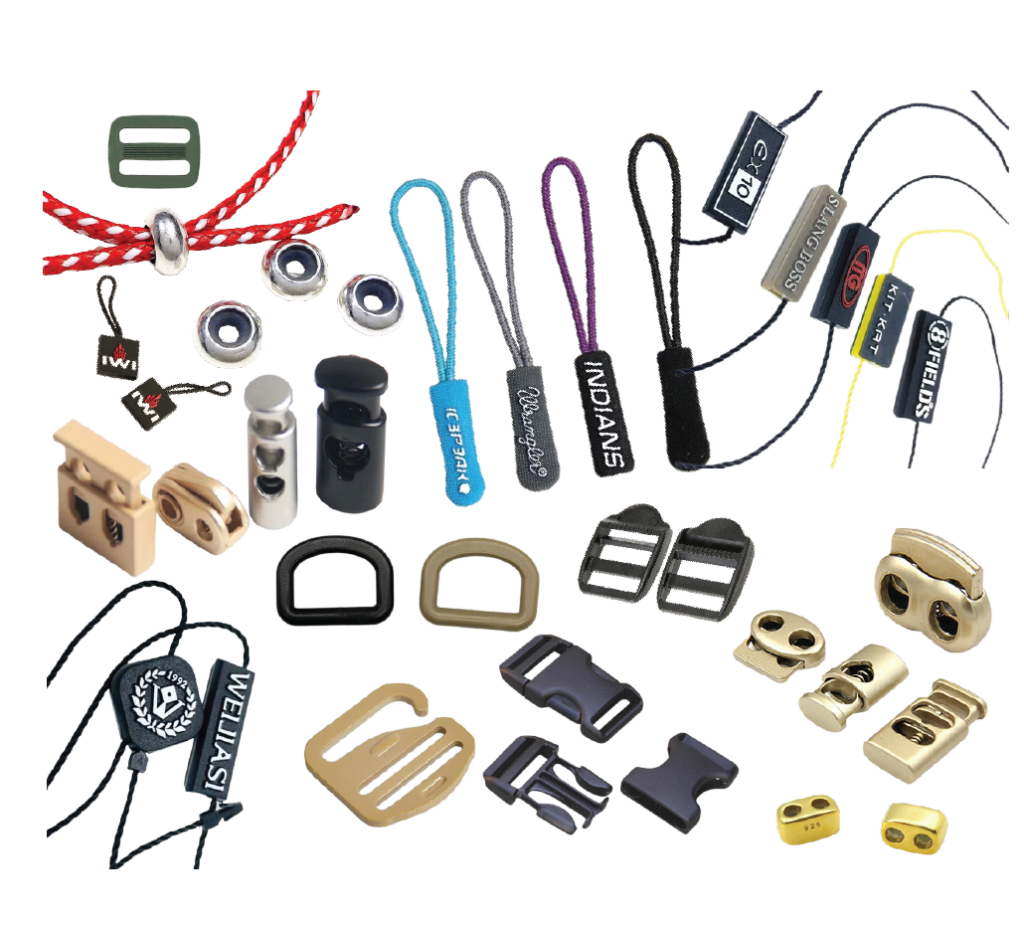

Specification Development: Clear and detailed specifications should be developed for each type of accessory. These specifications should outline the required materials, dimensions, colors, finishes, and any other relevant characteristics.

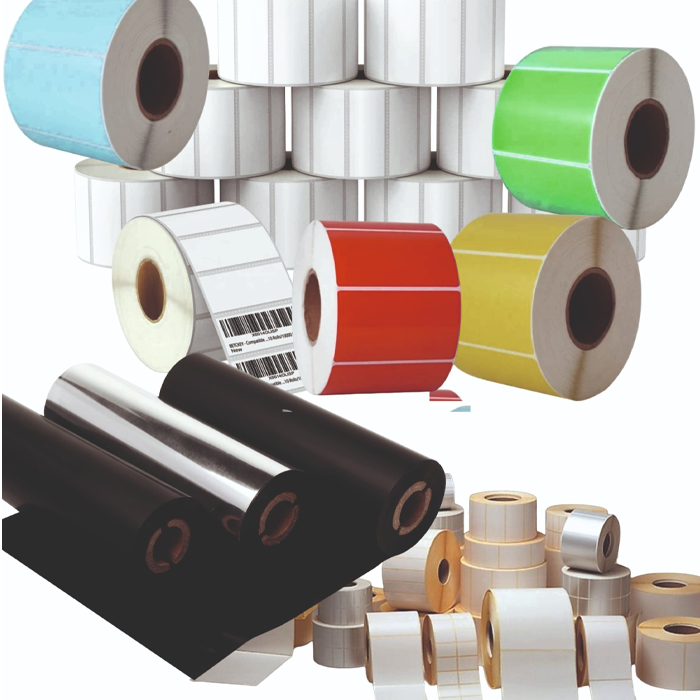

Incoming Material Inspection: When the accessories arrive at the manufacturing facility, they should undergo an initial inspection to ensure they match the provided specifications. This might involve measuring dimensions, checking color consistency, and verifying the quality of materials.

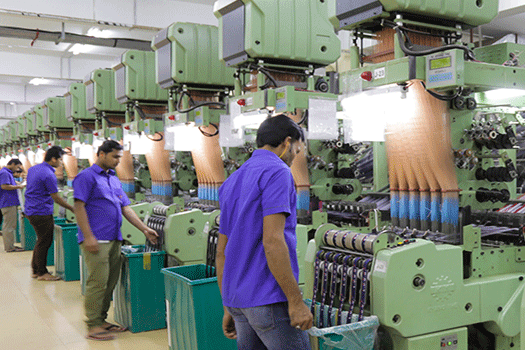

In-Process Inspections: During the manufacturing process, various checkpoints should be established to inspect the accessories at different stages. This helps identify and rectify any issues early in the production process.

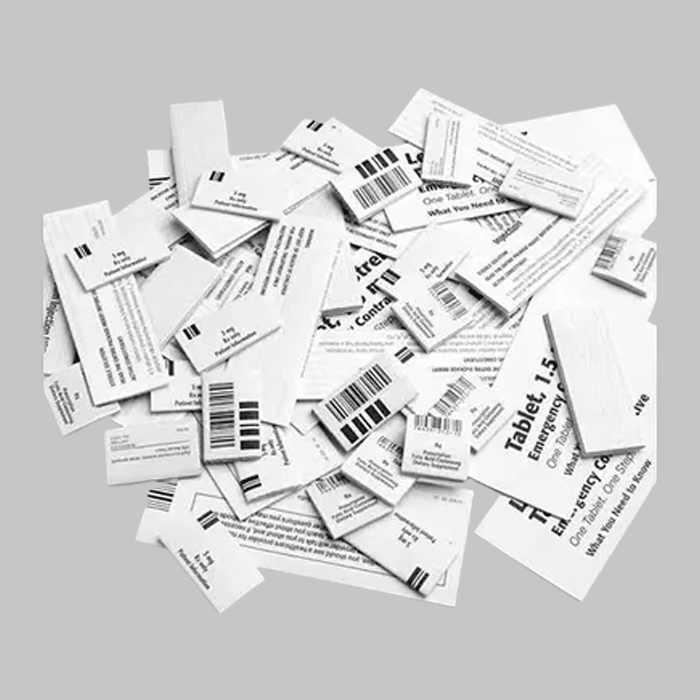

Functional Testing: Depending on the type of accessory, functional tests might be necessary. For example, zippers might be tested for smoothness of operation, buttons for secure attachment, and labels for legibility and durability.

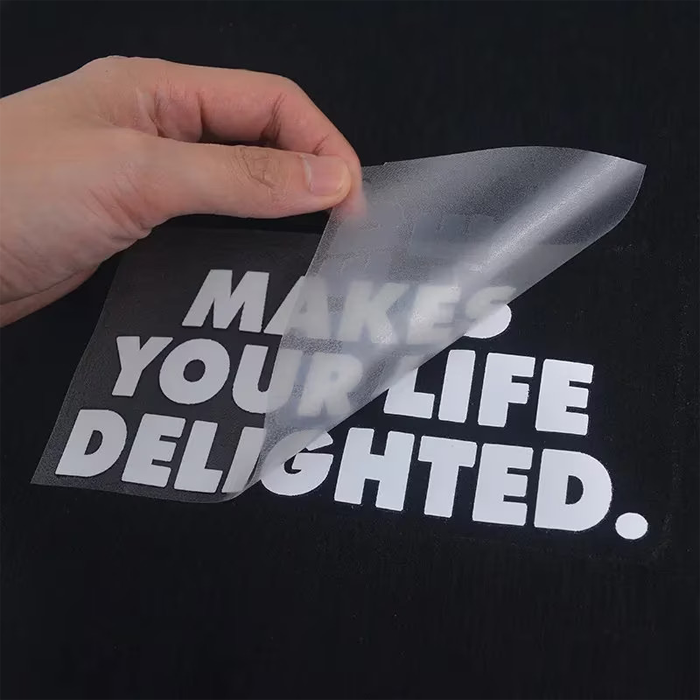

Visual Inspection: A visual inspection is essential to identify any defects in appearance, such as scratches, discolorations, misalignments, or inconsistencies in printing or embossing.

Sampling: Random samples of accessories should be selected from production batches and thoroughly inspected to ensure representative quality.

Lab Testing: Some accessories might need to undergo laboratory testing, especially if they have specific performance requirements, such as buttons needing to withstand a certain amount of force.

Packaging Inspection: The quality of packaging materials, labeling, and correct quantities of accessories per package should be verified.

Documentation and Records: All inspection results, testing outcomes, and related data should be documented for traceability and analysis. This documentation is essential for addressing any quality issues and for future reference.

Final Inspection: Once the accessories are ready for shipment, a final inspection should be conducted to ensure that the overall quality meets the set standards.

Feedback and Continuous Improvement: If any defects or issues are identified, feedback should be provided to suppliers, and corrective actions should be taken to prevent similar issues in the future. This continuous improvement process helps enhance the overall quality of the accessories.

Compliance with Regulations: Depending on the region and industry, there might be specific regulations or standards that the garment accessories need to comply with, such as safety regulations regarding the use of certain materials.